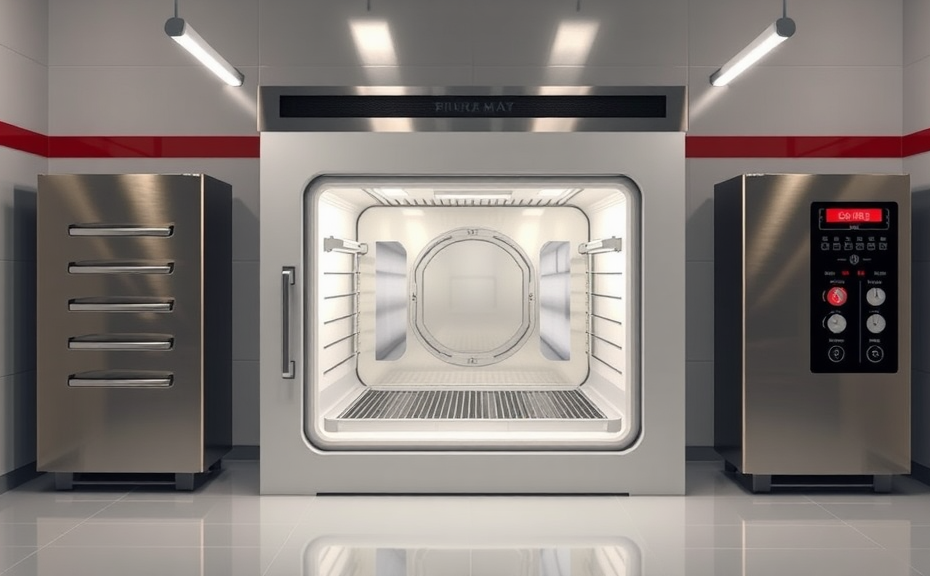

Powder coat ovens are essential equipment for any business engaged in powder coating applications. These specialized ovens are designed to provide consistent and controlled heating, ensuring that the powder adheres properly to the substrate during the curing process. By maintaining precise temperature and airflow, powder coat ovens create a suitable environment for achieving high-quality finishes on a variety of materials.

One of the primary advantages of using powder coat ovens is their ability to enhance the durability of the coatings. Unlike traditional liquid paints, powder coatings can create a thicker and more resilient finish that can better withstand corrosion, chipping, and fading. This makes them especially popular in industries such as automotive, aerospace, and manufacturing, where durability is paramount.

- Temperature Control: Powder coat ovens typically feature advanced temperature control systems that allow operators to set and maintain specific curing temperatures based on the type of powder being used.

- Efficient Design: Many powder coat ovens are designed with energy efficiency in mind, helping businesses save on operating costs while maintaining optimal performance.

- Size Variability: These ovens come in various sizes to accommodate different production needs, from small batch operations to large-scale manufacturing lines.

Moreover, the versatility of powder coat ovens extends beyond just metal surfaces. They can be used for plastics, wood, and ceramics, making them a valuable asset in diverse applications. As companies seek to enhance their finishing processes with eco-friendly options, powder coating and the use of powder coat ovens are becoming increasingly popular.

In summary, investing in a quality powder coat oven not only improves the aesthetic appeal of finished products but also significantly boosts their longevity and performance. For businesses looking to elevate their coating capabilities, these ovens represent a smart solution to achieving superior results.